Alarm Check Valve Operation

Fm global 92 922 views.

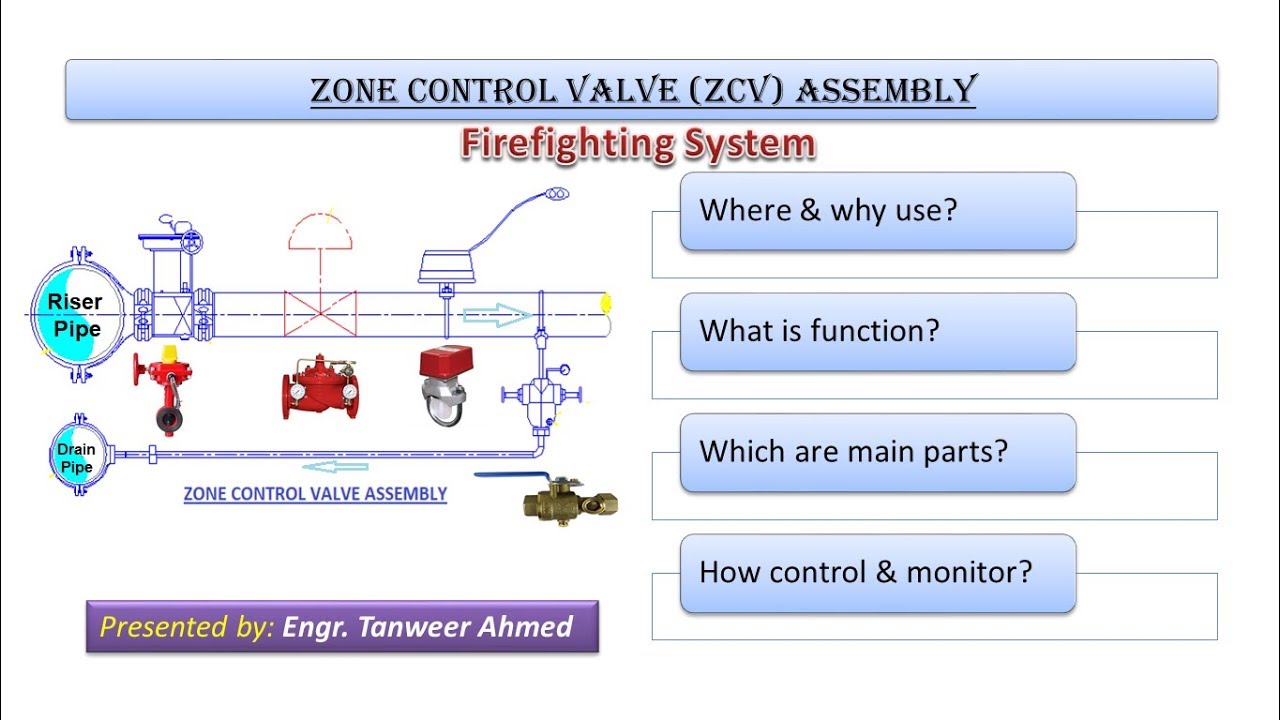

Alarm check valve operation. It serves a dual purpose which prevents a reverse flow of water non return also provides for the use of the water motor gong. The valve is designed to initiate an alarm during a sustained flow of water such as the flow required by an open sprinkler by operating an optional water motor. An alarm check valve can be activated or opened in one of two basic ways. Alarm valve is a double seated clapper check valve with grooved seat design which ensures positive water flow for alarm operation and is designed for installation in wet pipe sprinkler system.

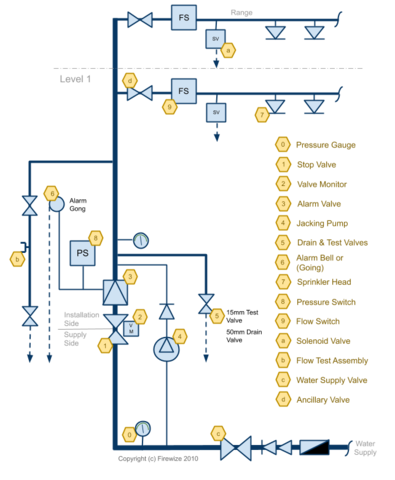

The viking model j 1 alarm check valve serves as a check valve by trapping pressurized water above the clapper and preventing reverse flow from sprinkler piping. Meanwhile in the event of variable pressure condition false alarm is prevented with provision of retard chamber at the external bypass. Alarm check valve is core element in wet pipe fire sprinkler systems. The wet alarm valve is designed for applications where the water is unlikely to freeze.

The main purpose of the alarm check valve is to ring a mechanical bell called a water motor gong. Once the alarm check valves are activated they will allow water to flow through the system engaging the sprinkler system as and where needed in order to suppress a potential fire. Wet system alarm check valve duration. Globe alarm check valve installation and maintenance guide important notes 1.

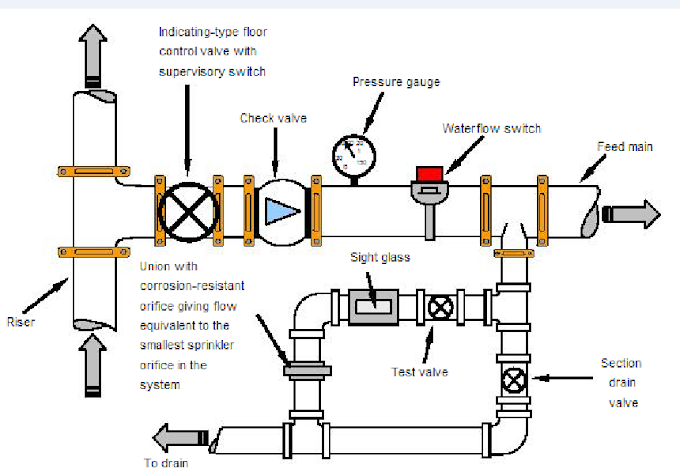

Fire fighting dry pipe valve operation duration. An alarm check valve is basically a check valve with an alarm port. The av 1 300 alarm check valve trim includes pressure gauges to monitor system pressure conditions a bypass check valve a main drain valve and an alarm test valve. Any alarm check valve should be carefully tested examined and cleaned periodically in accordance with nfpa 25.

In the event of variable pressure condition false alarm. It is most important to ensure a clean water supply free of debris and solid particles such as sand gravel or mud. The valve should if properly maintained help hold the system pressure steady and reduce the possibility of false alarms. Wet system valves water motor alarm model av 1 300 alarm check valve 300 psi 20 7 bar 2 1 2 to 8 dn65 to dn200 vertical or horizontal installation model rc 1 retard chamber for variable pressure wet pipe sprinkler systems 300 psi 20 7 bar model wma 1 water motor alarm hydraulically operated mechanical sprinkler alarm.

The bypass check valve reduces the possibility of false alarms by permitting slow as well as small transient increases in water supply pressure to be passed through. Either manually when a person activates a water gong or electronically.